Hydrogen and the facts about IIC or IIB+H2 explosion proof enclosures

22 January 2025

Hydrogen is one of the most abundant but dangerous gases on our planet. It has many uses and is set to form a big part of the energy transition, but the prevention of explosions is critical to its success throughout the supply chain.

Laurent Thomassin from Ex-tech Solution talks about the science of hydrogen explosions and why explosion proof enclosures for hydrogen applications are different to those typically found in the oil and gas industry.

What is hydrogen and is it flammable?

Hydrogen is the most abundant element on earth and capable of chemical reactions that generate energy, so it’s no wonder that hydrogen is in great demand. In fact, about 78% of the air we breathe is hydrogen and about 11% of water contains hydrogen. This colourless, odourless gas known as H2 is also not toxic or radioactive, and so has many different uses.

Over recent years, hydrogen and fuel cell technologies have shown significant potential to enable the transition to a clean, low-carbon energy system that helps reduce greenhouse gas emissions and limit climate change. And when hydrogen is burnt, or used to produce electricity, the only waste product is water.

However, there are challenges when using it. It is extremely flammable and considered one of the most dangerous gases, with several unique properties that make it dangerous to handle without the correct understanding and explosion protection equipment.

How is hydrogen made?

It takes a lot of energy!

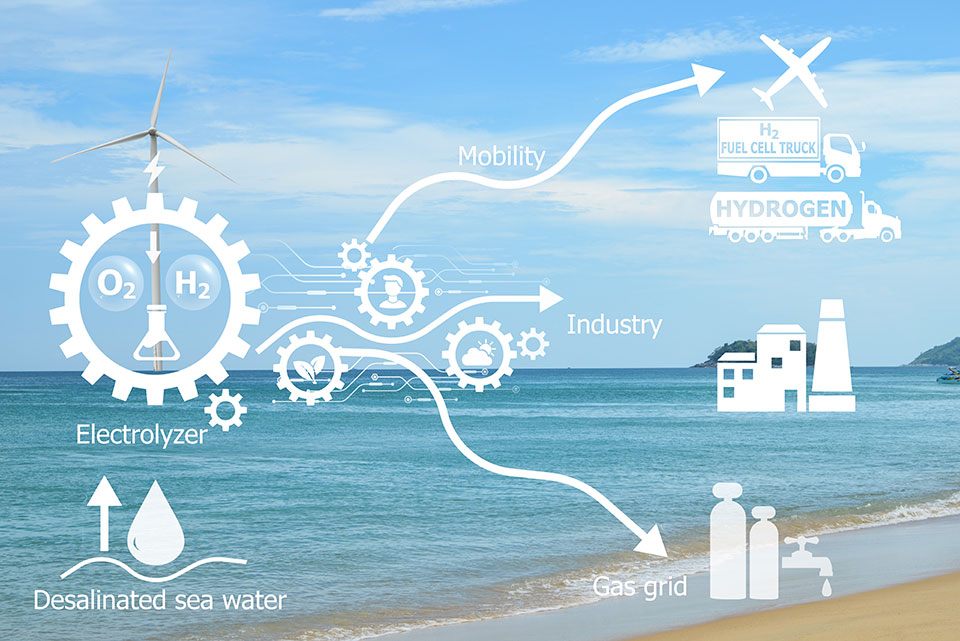

Electrolysis of water atoms is one of the best methods to produce hydrogen by electric current and is considered environmentally friendly with no carbon dioxide produced when wind or solar is used. This is known as green hydrogen which has grown over recent years. Grey hydrogen on the other hand is harmful to the environment.

Why is hydrogen more in demand in 2025?

Green hydrogen is considered by many as a fundamental part of the clean energy mix and the fuel of the future.

Furthermore, when used in transport systems it produces no tail-pipe emissions. However there are explosion risks throughout the supply chain.

The science of hydrogen explosions

Hydrogen + Oxygen + ignition source = Explosion

Like all other flammable material, an explosion can only occur when all three parts of the ignition triangle come together. That’s no different to hydrogen. See fire triangle diagram on the right.

With hydrogen, the fire and explosion burns with extreme heat. But what is more frightening, is that it burns with an invisible flame (to the human eye).

Hydrogen also explodes with enormous energy, requiring only a small amount of gas to cause significant damage which can lead to melting and further fires and explosions in the surrounding areas.

Hydrogen’s extremely large explosion range and high flame velocity means the resulting rapid pressure increase of hydrogen explosions are of particular importance for explosion protection specifications.

In other words, explosion protection for hydrogen needs to be different to that of natural gas.

Furthermore, Hydrogen has a very low minimum ignition energy (MIE) of just 0.0017 millijoules (mJ) at a stoichiometric mixt. That means it can be easily ignited by most sources. This is significantly lower than other flammable gases, like methane, which typically have an MIE of over 100 mJ.

Risk assessments according to ATEX in Europe, lead to the classification of hazardous areas and the resulting need for explosion proof equipment with the correct design specifications for hydrogen.

Hydrogen is a IIC gas which is different to natural gas. But why does that matter?

All known gases are categorised into groups based on their minimum ignition energy (MIE), which is the amount of energy required to ignite the gas with an electrical spark.

The IIC group has the lowest MIE, meaning that the gases in this group are highly volatile and easily ignited. Gases in the IIC group include hydrogen, acetylene, and carbon disulphide.

By contrast, Group IIA contains gases like propane and butane, and Group IIB contains ethylene and ethyl ether which aren’t as volatile or easy to ignite, but highly dangerous, nonetheless.

The IIC group is therefore the most severe of the gas groups, and equipment marked for use in IIC areas can also be used in IIB and IIA areas. However, equipment marked for use in IIB areas can only be used in IIB and IIA areas, and not in IIC areas.

It’s important to use equipment rated for the most volatile gas in the area.

The design of explosion proof enclosures for hydrogen hazardous area applications

A typical explosion proof ex d enclosure usually houses electrical items in a hazardous area at a factory or in a process area. Ex d enclosures work by containing explosions and preventing them from igniting the surrounding area. That’s if the gas can enter the enclosure in the first place.

Hydrogen molecules are smaller and can travel through narrow gaps more easily.

The enclosure contains an explosion and dissipates any excess energy through its flanges and threads. The enclosure has a flame path that cools and contains the explosion.

However, hydrogen is a gas that has different characteristics compared to most gases in industry such as methane or propane for example, which means the enclosures do need to be different than those seen in most hazardous areas.

That’s because hydrogen molecules are smaller and can travel through narrow gaps more easily. The design of the explosion proof enclosure therefore needs to be different to that of a IIA or IIB gas.

IIB+H2 enclosures have thinner and sometimes longer gaps than Group IIB enclosures – like this made by Ex-tech Solution

IIB+H2 enclosures have thinner and sometimes longer gaps than Group IIB enclosures. IIC explosion proof enclosures often have a cylindrical or threaded flame-path, while Group IIA and IIB enclosures have a flat flame-path.

An example of an explosion proof enclosure for hydrogen applications can be seen here, made by Ex-tech Solution.

When working in hazardous areas, it’s also important to be aware of the risks and use electrical equipment with the correct T rating (temperature class).

Where is explosion protection needed in the hydrogen supply chain?

The locations where explosion protection is needed span the entire hydrogen supply chain due to its dangerous characteristics. Here are some examples:

- Production: Electrolysis plants, oil, gas, coal applications, reforming plants, storage tanks and shipping infrastructure.

- Storage and distribution: Terminals, energy providers, transport networks and local storage depots

- Use: Manufacturing plants converting hydrogen in their process to fuels, methanol, ammonia, steel, glass, energy, cement, chemicals and much more. And of course transport users, the feeding of hydrogen into the natural gas grid and the use of hydrogen for the fermentation process in biogas plants, to name a few.

Ex d IIB+H2 explosion proof enclosure options

Explosion proof enclosures are used to protect electrical and control systems, such as energy distribution, process monitoring and machinery control.

The explosion proof enclosures for hydrogen must be strong enough to contain a significant explosion and, for example, the external wall of the enclosure must remain cool enough to prevent igniting a hydrogen-oxygen mixture outside the enclosure. Here are some examples:

IIB+H2 Stainless Steel Ex d enclosures – DE8BC

Here is an example of the stainless steel DE8BC Ex d IIB + H2 explosion proof enclosures from Ex-tech Solution, which have excellent corrosion resistance for marine / offshore applications, and are available in many sizes. They can be configured as Ex d direct entry or as an Ex de combination for indirect entry. If required, several enclosures can be assembled on a frame with separate or common Ex e/i junction boxes. Ex-tech Solutions can deliver the enclosures empty with a U component certificate, or will supply fully assembled according to customer’s needs.

IIB+H2 Copper Free Aluminium Ex d explosion proof enclosures – EJB

Ex-tech Solution’s EJB range of Ex d IIB +H2 explosion proof enclosures are manufactured in copper free aluminium and designed for use in control, check, signal, automation, interruption and protection applications. Copper free aluminium is often specified for its corrosion resistance and lighter weight.

IIB+H2 Carbon steel painted Ex d explosion proof enclosures – DE8BC

The DE8BC range of Ex d IIB or Ex d II B + H2 explosion proof enclosures range from Ex-tech Solution is manufactured in painted carbon steel and can also be configured as Ex d direct entry or as an Ex de combination for indirect entry. This is perfect for indoor heavy industrial use.

IIB+H2 Stainless Steel Ex d explosion proof enclosures – EJB

Another stainless steel option includes the EJB range of Ex d IIB + H2 explosion proof enclosures which are designed for control, check, signal, automation, interruption and protection use. If required, several enclosures can be assembled on a frame with separate or common Ex e/i junction boxes. The enclosures can also be delivered empty with a U component certificate or supplied fully assembled according to client demands.

Stainless steel enclosures are generally considered to be a better choice than carbon steel enclosures because they are stronger, more durable and resistant to corrosion,

Ex-tech Solution in the hydrogen supply chain

From explosion protection solutions at the source of hydrogen production, to ensuring safety in the storage and transportation, or protecting the end users of hydrogen, Ex-tech Solution is there to support.

With a wide range of explosion protection equipment designed, built and certified for hydrogen applications, we are there through the development journey as the hydrogen industry evolves with innovations helping to protect people, their investment and our environment.

Contact the Ex-tech Solution team for further advice and support.

By contrast, Group IIA contains gases like propane and butane, and Group IIB contains ethylene and ethyl ether which aren’t as volatile or easy to ignite, but highly dangerous, nonetheless.

By contrast, Group IIA contains gases like propane and butane, and Group IIB contains ethylene and ethyl ether which aren’t as volatile or easy to ignite, but highly dangerous, nonetheless.